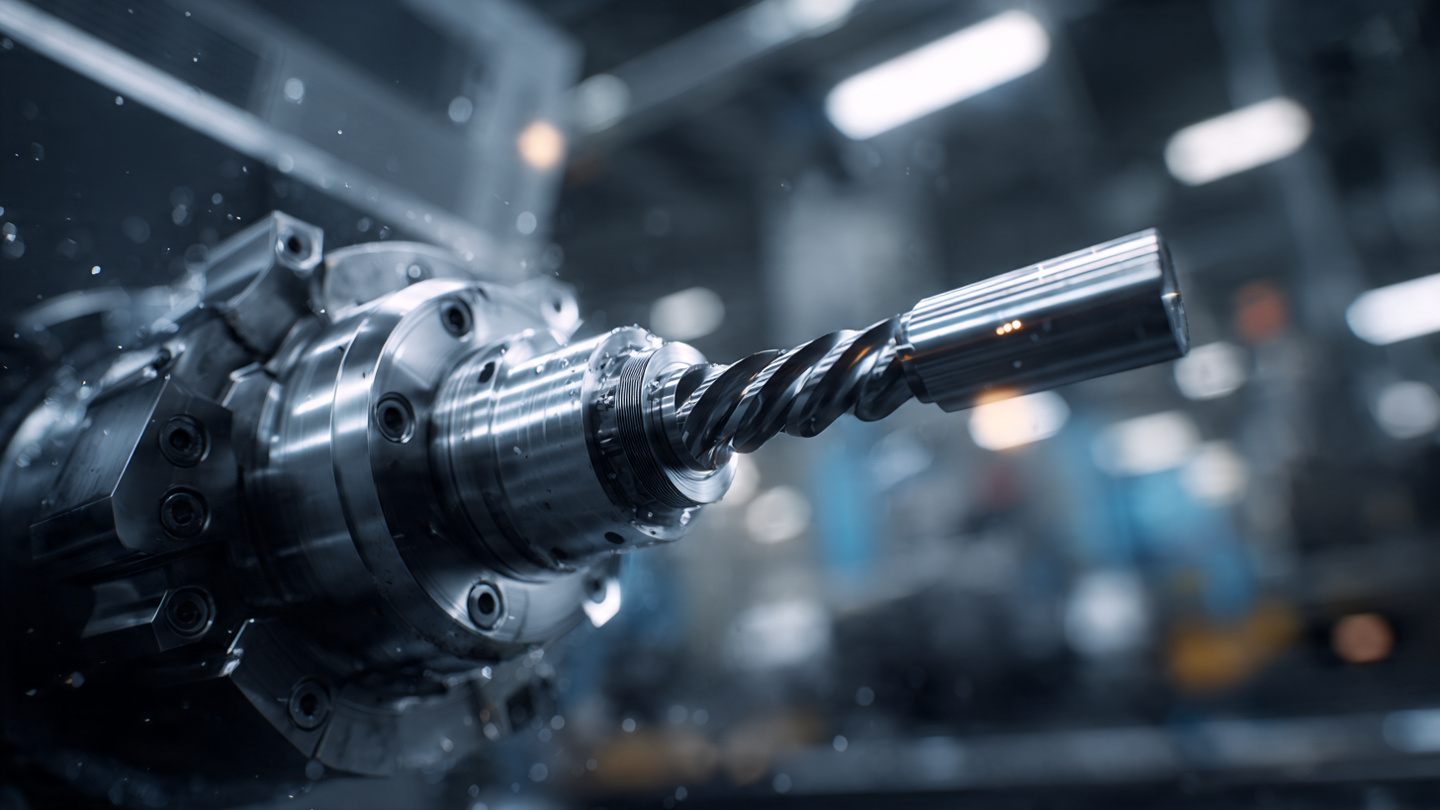

A winkelbohrspindel is a special mechanical tool used in machines to help drill or work at an angle. The word may look long and hard, but the idea behind it is simple. A winkelbohrspindel helps machines reach places that are not straight or easy to access. Instead of drilling straight down, this tool allows drilling or working sideways or at a specific angle. This makes it very useful in many machines where space is tight or where straight drilling is not possible. The winkelbohrspindel is designed to be strong, accurate, and reliable, so it can work for a long time without problems. Understanding what a winkelbohrspindel is and how it works helps people see why it is so important in modern machines.

What Is a Winkelbohrspindel?

A winkelbohrspindel is a mechanical part that changes the direction of movement from straight to angled. The word comes from German, where “winkel” means angle and “bohrspindel” means drilling spindle. So, a winkelbohrspindel is an angled drilling spindle. It is usually attached to a machine and helps the machine perform tasks at an angle that would otherwise be impossible. This tool is made with precision so it can move smoothly and accurately. Without a winkelbohrspindel, many machines would not be able to complete complex jobs that require angled movement.

Why Winkelbohrspindel Is Important

The winkelbohrspindel is important because it solves a big problem in machining: limited space. Many machines cannot reach certain areas if they only move straight. With a winkelbohrspindel, the machine can work around corners and into tight spots. This saves time, reduces mistakes, and makes work easier. The winkelbohrspindel also improves accuracy, which means the final product is made exactly the way it should be. Because of this, many industries depend on this tool for daily work.

How a Winkelbohrspindel Works

A winkelbohrspindel works by transferring motion from the machine into an angled direction. Inside the tool, there are gears that change the direction of rotation. When the machine spins, the winkelbohrspindel takes that spinning movement and turns it sideways or at a set angle. This allows tools attached to the spindle to drill or work in places that are hard to reach. The design is very smart because it keeps the movement smooth while changing direction. This smooth movement helps reduce wear and tear and keeps the tool working longer.

Parts of a Winkelbohrspindel

A winkelbohrspindel has several important parts that work together. The main body holds everything in place and protects the inside parts. Inside, there are gears that change the direction of motion. There is also a shaft that connects the spindle to the machine. Bearings help the parts spin smoothly without too much friction. Each part of the winkelbohrspindel is carefully designed so the tool can work accurately and safely. If one part is not made correctly, the whole tool may not work well.

Materials Used in Winkelbohrspindel

A winkelbohrspindel is usually made from strong materials like hardened steel. These materials are chosen because they can handle high pressure and constant movement. The gears inside must be very tough so they do not break or wear out quickly. The outer body is also made strong to protect the inside parts. Using good materials helps the winkelbohrspindel last longer and perform better, even in tough working conditions.

Types of Winkelbohrspindel

There are different types of winkelbohrspindel, each made for a specific job. Some are small and used for light work, while others are big and used for heavy machines. Some winkelbohrspindels have fixed angles, meaning they always work at the same angle. Others can be adjusted to different angles. Choosing the right type of winkelbohrspindel depends on the job that needs to be done. Using the correct type helps improve speed and accuracy.

Where Winkelbohrspindel Is Used

A winkelbohrspindel is used in many machines where angled work is needed. It is common in manufacturing machines that make metal or other materials. It is also used when machines need to drill holes on the side of an object instead of the top. Because it allows flexible movement, the winkelbohrspindel is helpful in many different machine setups. Wherever there is a need to work at an angle, this tool becomes very useful.

Advantages of Using Winkelbohrspindel

One big advantage of a winkelbohrspindel is that it saves time. Machines do not need to be repositioned again and again. Another advantage is accuracy. The tool helps machines work exactly where they need to, even in tight spaces. The winkelbohrspindel also helps reduce mistakes because it keeps the tool steady while working. These advantages make it a popular choice in machine design.

Limitations of Winkelbohrspindel

Even though a winkelbohrspindel is very useful, it has some limits. It can be more expensive than simple tools because of its complex design. It also needs proper care and maintenance to work well. If not maintained, the gears inside may wear out. However, when used correctly, these limits are small compared to the benefits.

Maintenance of Winkelbohrspindel

Proper maintenance is very important for a winkelbohrspindel. Regular cleaning helps remove dust and metal particles. Lubrication keeps the gears moving smoothly. Checking for wear and damage helps prevent sudden breakdowns. With good care, a winkelbohrspindel can last a long time and continue to work accurately.

Safety While Using Winkelbohrspindel

Safety is important when using a winkelbohrspindel. The tool should always be attached correctly to the machine. Operators should make sure it is secure before starting work. Wearing protective gear is also important. A well-maintained winkelbohrspindel is safer because it runs smoothly and does not cause sudden movements.

One Detailed Explanation of Winkelbohrspindel

A winkelbohrspindel is a carefully designed tool that allows machines to perform angled work with high accuracy and efficiency, making it an essential part of modern mechanical systems where straight movement alone is not enough, because many machine tasks require reaching around corners or working in tight areas, and the winkelbohrspindel solves this problem by using internal gears that smoothly change the direction of motion without losing power or precision, which means the machine can continue working as expected while saving time and effort, and because it is made from strong materials and built with precision, the winkelbohrspindel can handle repeated use and heavy workloads, making it reliable for long-term use, while also helping improve the quality of the final product by ensuring clean and accurate work even in difficult positions.

How to Choose the Right Winkelbohrspindel

Choosing the right winkelbohrspindel depends on the job. The size of the machine, the angle needed, and the type of work all matter. It is important to pick a tool that matches the machine’s power and speed. Using the correct winkelbohrspindel helps avoid damage and improves performance.

Future of Winkelbohrspindel

The future of the winkelbohrspindel looks promising. As machines become more advanced, the need for flexible tools will grow. New designs may make winkelbohrspindels smaller, stronger, and more efficient. This will help machines do even more complex tasks with ease.

Frequently Asked Questions About Winkelbohrspindel

What does a winkelbohrspindel do?

A winkelbohrspindel helps machines work at an angle instead of straight.

Why is a winkelbohrspindel useful?

It allows machines to reach tight or hard-to-reach places easily.

Is a winkelbohrspindel hard to use?

No, when installed correctly, it works smoothly with the machine.

Does a winkelbohrspindel need maintenance?

Yes, regular cleaning and lubrication help it last longer.

Can one winkelbohrspindel fit all machines?

No, different machines need different types of winkelbohrspindel.

Conclusion: A Detailed Look at Winkelbohrspindel

The winkelbohrspindel is an important tool that makes modern machines more flexible and powerful. By allowing angled movement, it helps machines complete tasks that would otherwise be very difficult or impossible. Its smart design, strong materials, and precise movement make it reliable and efficient. Although it needs proper care and correct selection, the benefits of using a winkelbohrspindel are far greater than its limits. As technology grows, this tool will continue to play a key role in machine work. Understanding the winkelbohrspindel helps everyone appreciate how machines achieve accuracy and efficiency, even in the smallest and tightest spaces.

Read More: Marciemcd25: Digital Identity, Online Presence, and Public Interest Explained