Meta Description: 5-axis CNC machining is the next big thing in aerospace manufacturing! This article discusses how it helps produce complex parts, cuts production time, and paves the way for eco-friendly aircraft.

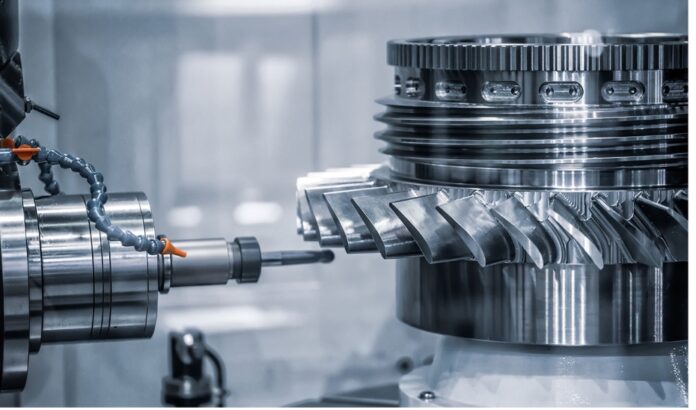

In the ever-evolving world of aerospace engineering, where precision and performance are crucial, 5-axis CNC machining emerges as a cornerstone technology, driving innovation and pushing the boundaries of what’s possible. 5-axis CNC machining is an advanced manufacturing process that utilizes computer numerical control (CNC) to craft cutting tools along five axes of motion simultaneously. This process enables the production of complex and intricately detailed components with unparalleled accuracy and efficiency.

By embracing this technology, aerospace manufacturers can achieve levels of precision and consistency that were once unimaginable, paving the way for safer, more efficient, and technologically advanced aircraft. However, there is more.

Hence, in this article, we’ll discuss the various applications of 5-axis CNC machining in the aerospace industry, ranging from fabricating turbine blades and engine components to intricate fuselage structures and aerodynamic wing sections. Also, we’ll highlight how this advanced manufacturing technique improves the aerospace industry’s journey towards sustainability, spearheading initiatives for zero-carbon flight and ushering in a new era of environmentally conscious aviation.

What is 5 Axis CNC Machining?

In manufacturing, Computer Numerical Control (CNC) machining is synonymous with precision and efficiency. Traditional machining methods often involve multiple setups and tool changes to produce complex components, leading to increased production time and higher costs. However, with the advent of 5-axis CNC machining, these limitations are eliminated, opening doors to impressive levels of precision and accuracy.

5-axis CNC machining involves utilizing computer-controlled machines equipped with five axes of motion: three linear axes (X, Y, Z) and two rotational axes (A, B or C). Unlike its 3-axis or 4-axis counterparts, which are confined to linear and rotational movements along fewer axes, 5-axis CNC machines offer additional freedom, enabling simultaneous movement in multiple directions. This feature allows for intricate machining operations on complex geometries with unprecedented precision.

The beauty of 5-axis CNC machining lies in its versatility and adaptability to many manufacturing challenges. By harnessing the power of advanced software algorithms and precision engineering, these machines can execute intricate toolpaths with remarkable efficiency, revolutionizing industries ranging from aerospace and automotive to medical and defense.

Common Applications of 5 Axis CNC Machining in Aerospace Industry.

Complex Components:

The aerospace industry demands components with intricate geometries and tight tolerances to meet the industry’s strict safety and performance standards. 5-axis CNC machining produces components, including turbine blades, engine housings, structural airframe parts, and complex fittings. By ensuring machining from multiple angles, these machines create intricate features and contours that would be impractical or impossible to achieve with conventional machining methods.

Reduced Setup Time:

In traditional machining processes, each setup change adds time and introduces opportunities for error. With 5-axis CNC machining, the need for multiple setups is minimized, as the machine can access various faces of the workpiece without repositioning. This reduction in setup time streamlines the manufacturing process, increases throughput, and ultimately lowers production costs.

Improved Efficiency:

Efficiency is paramount in aerospace manufacturing, where deadlines are tight, and precision is non-negotiable. 5-axis CNC machining offers a significant boost in productivity by enabling continuous and uninterrupted machining operations. Eliminating the need for frequent tool changes and repositioning ensures these machines maximize spindle uptime and minimize idle time, resulting in faster turnaround times and increased throughput.

Prototyping and Rapid Manufacturing:

Rapid prototyping and manufacturing are essential for staying ahead of the competition in the fast-paced world of aerospace development. 5-axis CNC machining facilitates rapid iteration and production of prototype parts with high precision and repeatability. Whether testing a new aerodynamic design or manufacturing a custom tooling fixture, these machines provide the agility and flexibility to bring ideas from concept to reality in record time.

Advantages of 5 Axis CNC Machining in Aerospace Industry.

5-axis CNC machining has improved the aerospace industry in various impressive ways. While this is not all, below are a few ways this technique has improved the industry.

Increased Precision:

Precision is the hallmark of aerospace manufacturing, where even the slightest deviation can have catastrophic consequences. 5-axis CNC machining delivers unmatched precision by allowing for simultaneous machining from multiple angles. This multi-axis capability ensures that complex features are machined accurately, resulting in parts that meet the strictest quality standards.

Reduced Lead Time:

Time-to-market is critical in the aerospace industry, where delays can result in lost opportunities and increased costs. 5-axis CNC machining shortens lead times by streamlining the manufacturing process and minimizing setup changes. With fewer setups and faster machining speeds, manufacturers can produce components more quickly and respond promptly to changing market demands.

Enhanced Surface Finish:

Surface finish plays a crucial role in the performance and longevity of aerospace components, particularly in applications involving high-velocity airflow or extreme temperatures. 5-axis CNC machining achieves superior surface finishes using advanced cutting strategies and precise toolpath control. This results in parts with smooth surfaces and tight tolerances, reducing friction, improving aerodynamics, and enhancing overall performance.

Cost Efficiency:

While the initial investment in 5-axis CNC machining may seem significant, the long-term cost savings are substantial. These machines offer a compelling return on investment over their lifespan by minimizing manual labor, reducing scrap, and optimizing production efficiency. Additionally, consolidating multiple machining operations into a single setup further reduces costs by eliminating the need for additional fixtures and tooling.

Versatility:

Aerospace manufacturers work with various materials, from lightweight alloys and composites to exotic metals like titanium and Inconel. 5-axis CNC machining is highly versatile and can accommodate the machining requirements of virtually any material. Whether roughing out aluminum bulkheads or finishing carbon fiber components, these machines offer the flexibility and adaptability needed to tackle the most challenging aerospace applications.

Limitations of 5 Axis CNC Machining in Aerospace Industry.

Like every other impressive technique in the manufacturing industry, 5-axis CNC machining does come with some drawbacks. Below are a few:

High Initial Investment:

The acquisition and maintenance costs of 5-axis CNC machines can be substantial, especially for small and medium-sized aerospace manufacturers. The training and infrastructure required to operate these machines effectively add to the initial investment. While the long-term benefits justify the upfront costs for many manufacturers, the initial barrier to entry can be a handful for some.

Complex Programming:

Maximizing the capabilities of 5-axis CNC machining requires skilled operators with a deep understanding of CAD/CAM software and advanced machining techniques. Programming a 5-axis machine requires expertise in multi-axis toolpath generation, collision detection, and optimization strategies. The programming complexity can challenge manufacturers transitioning from traditional machining methods and may require additional training and resources.

Tool Access:

In certain configurations, 5-axis CNC machines may have limited access to some regions of the workpiece, particularly in deep pockets or complex geometries. This limitation requires specialized tooling or creative workholding solutions to ensure adequate tool access and maintain machining efficiency. While modern machine designs strive to minimize tool access restrictions, they remain a consideration when selecting machining strategies and tooling configurations.

Potential for Errors:

The increased complexity of 5-axis machining introduces additional opportunities for error, ranging from programming mistakes to mechanical issues. Collision detection software helps mitigate the risk of tool and machine collisions, but human error remains a factor. Manufacturers must implement robust quality control measures to identify and rectify mistakes early in the machining process to minimize scrap and rework.

Material and Tool Limitations:

While 5-axis CNC machining is highly versatile, specific materials and tooling configurations may pose challenges. Exotic materials like titanium and nickel-based alloys require specialized cutting tools and machining strategies to achieve optimal results. Additionally, the size and geometry of the workpiece may limit the selection of suitable tooling and machining approaches. Manufacturers must carefully consider material properties and machining requirements when planning 5-axis machining operations to ensure success.

Zero-carbon Flight: 5-axis CNC Accelerates Airlines’ Green Development Path.

In an era of increasing environmental awareness and sustainability initiatives, the aerospace industry faces mounting pressure to reduce its carbon footprint. Aircraft manufacturers and airlines actively seek innovative solutions to minimize emissions and improve fuel efficiency, aiming to achieve zero-carbon flight.

Integrating precision 5-axis CNC machining in aerospace manufacturing is key to advancing this green development path. By enabling the production of lightweight components with intricate designs, 5-axis CNC machining contributes to aircraft’s overall efficiency and sustainability. Lighter aircraft consume less fuel and produce fewer emissions, making them more environmentally friendly and cost-effective over their operational lifespan.

Furthermore, 5-axis CNC machining facilitates the development of advanced aerospace materials and components that further enhance fuel efficiency and performance. From lightweight structural components to aerodynamically optimized surfaces, these innovations enable aircraft to fly farther, faster, and with fewer environmental impacts.

Adopting 5-axis CNC machining can help airlines and aircraft manufacturers realize significant environmental and economic benefits. Reduced fuel consumption, lower emissions, and increased operational efficiency are just a few of the advantages contributing to a greener and more sustainable future for air travel.

Conclusion.

5-axis CNC machining is a cornerstone of innovation in the aerospace industry, offering unparalleled precision, efficiency, and versatility. Its diverse and far-reaching applications, from complex components to rapid prototyping, drive aircraft design and manufacturing advancements.

While the advantages of 5-axis CNC machining are undeniable, it is essential to acknowledge its limitations and challenges. High initial investment costs, complex programming requirements, and material constraints must be carefully considered and managed to maximize the technology’s benefits.

Nevertheless, 5-axis CNC machining’s potential to accelerate the aerospace industry’s green development path is undeniable. As technology evolves and manufacturing processes become increasingly sophisticated, 5-axis CNC machining will become more prominent and propel the industry toward a more efficient, sustainable, and environmentally friendly future.